Retailers today face tightening margins, higher storage costs, and fluctuating consumer demand. A slow-moving inventory ties up cash, clogs warehouse space, and risks markdowns that eat into profitability.

According to a 2024 NRF study, retailers with faster inventory turnover rates (8-12 turns per year) see up to 18% higher profit margins compared to those with sluggish turnover (4-6 turns).

To improve cash flow and profitability, retailers need to accelerate inventory turnover without over-discounting, using a combination of demand forecasting, supplier collaboration, technology integration, and optimized pricing strategies.

Table of Contents

Toggle1. Demand Forecasting with Advanced Analytics

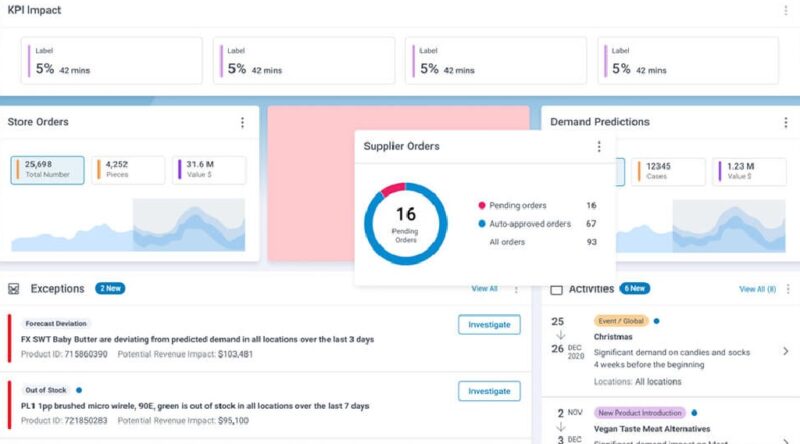

Advanced demand forecasting goes beyond seasonal charts and gut instincts by using AI and machine learning tools to predict customer demand accurately.

By analyzing historical sales, local events, weather patterns, and macroeconomic indicators, predictive models generate demand forecasts that adjust dynamically.

Systems like Blue Yonder, Google Cloud AI, and SAS Retail Forecasting can break down forecasts by SKU, store, or region, helping you order just enough to meet demand without overstocking.

Example

A U.S. apparel chain implemented machine learning-based forecasting and saw a 29% reduction in stockouts and a 21% decrease in excess stock, freeing over $1 million in working capital within a year.

Demand Forecasting Impact

| Metric | Before | After Advanced Forecasting |

| Forecast Accuracy | 68% | 91% |

| Stockouts | 16% | 11% |

| Excess Inventory | 20% | 12% |

Predicting what customers will buy keeps shelves stocked efficiently while avoiding costly over-purchasing.

2. Implement Just-In-Time (JIT) Inventory Practices

JIT involves receiving goods only as they are needed, reducing the need for large warehouse spaces and capital tied up in unsold inventory. It requires tight supplier relationships, real-time sales tracking, and quick logistics support to replace stock immediately after a sale.

Retailers integrate JIT by connecting POS systems to suppliers so low-stock triggers automatic reorders. This ensures consistent product availability while avoiding excess stock buildup.

Example

An electronics retailer in Canada switched to JIT for accessories, reducing on-hand inventory by 35% and improving turnover from 7x to 10x annually, freeing $750,000 in tied-up cash.

JIT vs. Traditional Inventory

| Aspect | Traditional | JIT |

| Order Size | Large | Small & frequent |

| Holding Costs | High | Low |

| Stock Levels | High | Optimized |

JIT enables efficient stocking without sacrificing availability, keeping inventory lean while serving customer demand.

3. Use Dynamic Pricing to Move Slow Stock

Dynamic pricing utilizes real-time data to adjust product prices based on demand, competitor pricing, and stock levels. AI tools analyze these data points to automatically tweak prices, helping clear slow-moving stock while maintaining acceptable profit margins.

For example, if a product isn’t selling as forecasted, prices can be adjusted before it becomes dead stock, attracting customers while preserving margins.

Example

A mid-sized outdoor gear retailer used Revionics to dynamically price slow-selling jackets, reducing aged stock by 22% over three months while maintaining average gross margins of 82%.

Dynamic Pricing Outcomes

| Metric | Before | After Dynamic Pricing |

| Aged Inventory | 19% | 9% |

| Markdown Losses | High | Lower |

| Margin Retention | 72% | 82% |

Dynamic pricing is a flexible way to maintain turnover and profitability without blanket discounts.

4. Strengthen Supplier Collaboration

Better supplier relationships facilitate flexible restocking, smaller batch ordering, and fast replenishment. Tools like EDI (Electronic Data Interchange) and shared dashboards allow suppliers to see your sales data, enabling them to plan production aligned with your demand.

Vendor-Managed Inventory (VMI) programs are an extension of this collaboration, allowing suppliers to directly replenish your stock as it sells, reducing administrative workload and errors.

Example

A grocery chain implementing VMI with major suppliers reduced safety stock by 30% and increased inventory turnover from 6x to 9x annually.

Supplier Collaboration Benefits

| Metric | Before VMI | After VMI |

| Safety Stock | High | Reduced |

| Stockouts | Common | Reduced |

| Turnover Rate | 6x | 9x |

Working closely with suppliers aligns supply with demand, ensuring consistent stock while minimizing excess.

5. Optimize Store Layout and Visual Merchandising

Strategic store layouts and visual merchandising help increase product visibility and accelerate sales velocity. Techniques include:

- Placing slow-moving items in high-traffic zones.

- Using end caps for promotional products.

- Cross-merchandising slow items with fast-moving products.

Heatmap analytics can reveal customer pathways, helping you adjust layouts for maximum exposure.

Example

A supermarket chain repositioned slow-moving organic snacks near checkout counters, increasing sales by 21% in two months.

Impact of Merchandising Optimization

| Metric | Before | After Merchandising |

| Visibility | Low | High |

| Sales Velocity | Slow | +21% |

| Turnover Rate | 5x | 7x |

Improved product placement can significantly boost turnover without extra marketing spend.

6. Automate Replenishment Processes

Retailers using automated replenishment linked to real-time sales data experience faster inventory turnover while minimizing manual errors. Systems like NetSuite or Oracle SCM trigger reorders when products hit pre-set thresholds, ensuring optimal stock levels without manual tracking. This frees staff to focus on customers instead of paperwork.

For e-commerce sellers and Amazon FBA users looking to speed up inventory turnaround while managing prep and storage efficiently, using a dedicated prep center can be transformative.

For example, Dollan Prep Center allows sellers to streamline FBA and e-commerce operations, ensuring products are prepped and shipped quickly while you monitor inventory levels remotely. This partnership approach speeds up inbound and outbound logistics, a critical component in reducing delays that often slow inventory cycles for online retailers.

Manual vs. Automated Replenishment

| Aspect | Manual | Automated/Partnered |

| Labor Hours | High | Low |

| Errors | Frequent | Rare |

| Restock Speed | Slow | Fast |

| Turnover Impact | Low | High |

7. Run Targeted Promotions to Clear Aged Inventory

Targeted promotions focus on specific customer segments using CRM data rather than broad discounts. Tactics include loyalty-based offers, flash sales for slow-moving products, or bundling aged items with popular products.

These promotions maintain margins while clearing space for new inventory.

Example

A beauty retailer cleared $100,000 in aged stock using targeted loyalty emails over a 45-day campaign while maintaining 75%+ margins.

Promotions Impact

| Metric | Blanket Discounts | Targeted Promotions |

| Margin Impact | High | Low |

| Engagement | Low | High |

| Sell-Through Rate | Moderate | High |

Targeted promotions move products strategically while building customer loyalty.

8. Use RFID and Real-Time Tracking

RFID tags track inventory movement in real-time, providing 98%+ accuracy in inventory data. This enables retailers to detect shrinkage, monitor shelf availability, and automate replenishment decisions efficiently.

Integrating RFID with POS systems creates seamless inventory transparency across the store and warehouse.

Example

A fashion retailer implementing RFID increased inventory accuracy from 80% to 98%, improving turnover rates from 6x to 9x annually.

RFID Benefits

| Metric | Pre-RFID | Post-RFID |

| Inventory Accuracy | 80% | 98% |

| Shrinkage | 2% | 0.5% |

| Turnover Rate | 6x | 9x |

RFID drives precise tracking for faster sales and reduced losses.

9. Reduce SKU Complexity for Focused Turnover

Streamlining SKUs enables focus on high-velocity, profitable products while reducing shelf clutter. Analyzing sales data to identify underperforming SKUs for discontinuation frees up resources for faster-selling items.

This approach improves sales per SKU and reduces the risk of dead stock.

Example

A home decor retailer reduced SKUs by 20%, increasing average sales per SKU by 28% within a quarter.

SKU Rationalization Outcomes

| Metric | Before | After Rationalization |

| Total SKUs | 1800 | 1440 |

| Sales/SKU | $480 | $615 |

| Turnover Rate | 5x | 8x |

Fewer, faster-selling SKUs maximize shelf productivity and cash flow.

10. Conduct Regular Inventory Audits

Regular audits identify dead stock, shrinkage, and discrepancies, allowing you to take corrective action early. This enables data-driven decision-making for markdowns, promotions, or liquidation before products age excessively.

Audits also validate system data, ensuring accurate inventory records for forecasting and replenishment.

Example

A sports retailer’s monthly inventory audits reduced aged inventory by 33% in 12 months, freeing $300,000 in working capital.

Audit Benefits

| Metric | Pre-Audit | Post-Audit |

| Aged Inventory | High | Reduced |

| Accuracy | Lower | Higher |

| Turnover Rate | 5x | 7x |

Conclusion

No single tactic will transform your retail turnover overnight. A systematic approach combining accurate forecasting, JIT practices, RFID, supplier partnerships, and targeted promotions will help you achieve:

- Reduced holding costs

- Improved cash flow

- Higher customer satisfaction

- Increased profitability

Regularly monitor inventory KPIs such as aged stock %, turnover rate, and shrinkage to measure progress.